Er5356 Welding Wire Specification

Er5356 materials are used mainly for welding aluminum of like composition.

Er5356 welding wire specification. The proper choice of aluminum filler metal mainly depends on the base metal properties to be achieved andwelding technique. Er5356 should be considered for welding 5000 series aluminum base metals. This type is also useful if color match is important after anodizing. 70 a minimum of 70 000 pounds of tensile strength per square inch of weld.

Harris er5356 1 16 aluminum tig welding wire 3 53563033pop 3 lb. Almg5cr a principle alloying elements. 6 the amount of deoxidizing agent and cleansing agent on the electrode this is a copper coating on the electrode and there are different types too. Er an electrode or filler rod that is used in either a mig wire feed or tig welding.

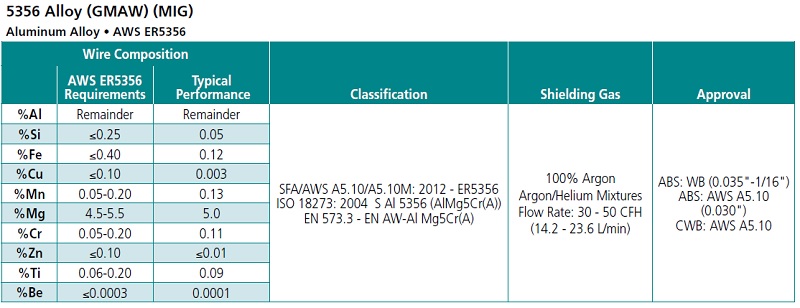

Er5356 data sheet pinnacle alloys er5356 aws class er5356 code and specification data. 4043 has lower shear strength than that of 5356 see fig 1. In addition it also offers excellent corrosion resistance when exposed to salt water. Ansi aws a5 10 er r packaging options.

Mig wire electrode label meaning for a er70s 6 label. The weld deposit of washington alloy 5356 offers much better corrosion resistance when exposed to salt water. This filler metal is a non heat treatable wire used to weld the 5xxx series base metals to themselves and other alloys. This may be of consideration when calculating the size of fillet welds.

Similar to alsi5 din iso designation. Typical semiautomatic gma procedures for fillet and lap welding aluminum 3 dc ep base1 dc ep wire argon approximate wire dia range 2thickness suggested feed gas flow consumption inches amps volts inches amps volts ipm cfh lbs 100ft 030 100 130 18 22 094 100 22 500 30 0 75. 4043 is a softer alloy in the form of spooled wire when compared to 5356. Tube of 36 inch lengths harris er5356 1 16 diameter aluminum tig welding wire used to weld the 5xxx series alloys when 40 000 psi tensile strength is not a requirement.

Magenesium maganese chromium titanium. Welding filler wire nail wire. Er5356 mig welding wire. Specifications aws sfa 5 10 er5356 description washington alloy 5356 commonly referred to as aimg5 is a 5 magnesium aluminum filler metal that is available for mig or tig welding processes.

Pinnacle alloys er5356 has a nominal composition wt of 5 mg balance al. Applications welding filler wire aws specification aws a5 10 a5 10m 1999 r2007 aws classification er5356 welding. Choose from various diameters of wire for different welders and welding projects. 4043 has lower ductility than that of 5356.

Er5356 is a general purpose type aluminium alloy which is typically chosen for its relatively high shear strength. Aws a5 10 asme sfa 5 10. 5356 is a very good all purpose wire so it is the most widely used of all aluminum fillers metals common applications are welding of boats ships.