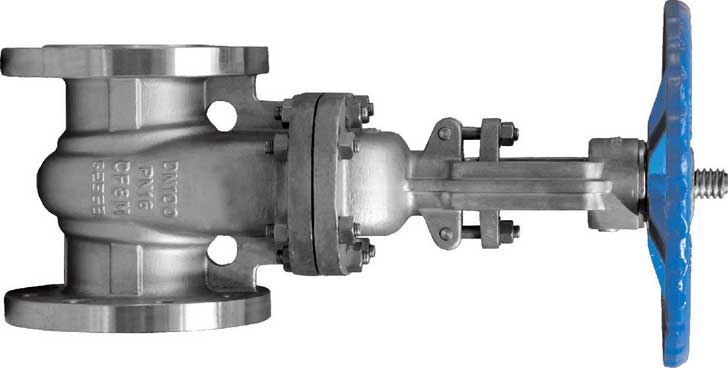

Double Expanding Gate Valve Definition

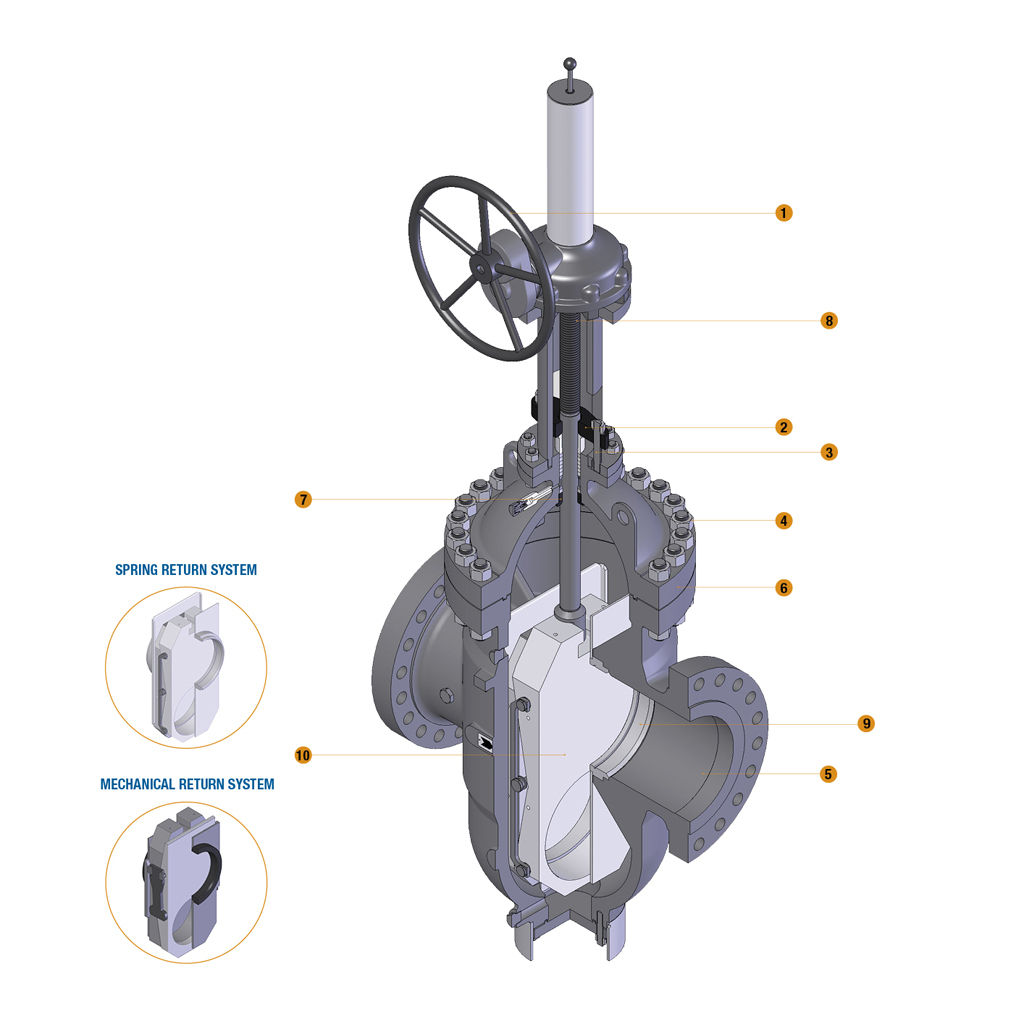

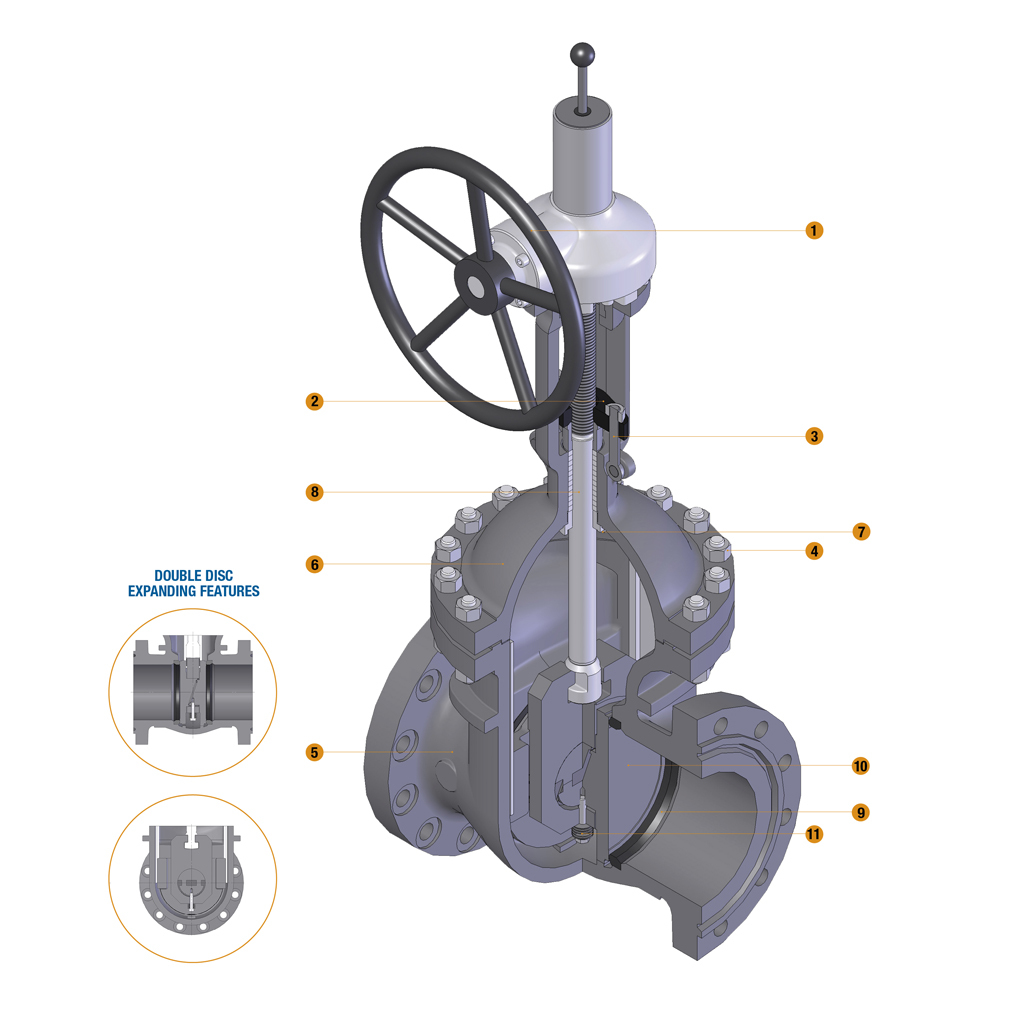

Consisting of a gate and a second segment male and female wedge segment.

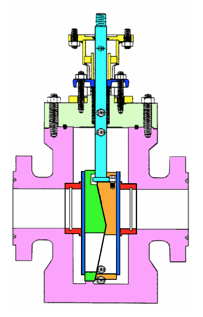

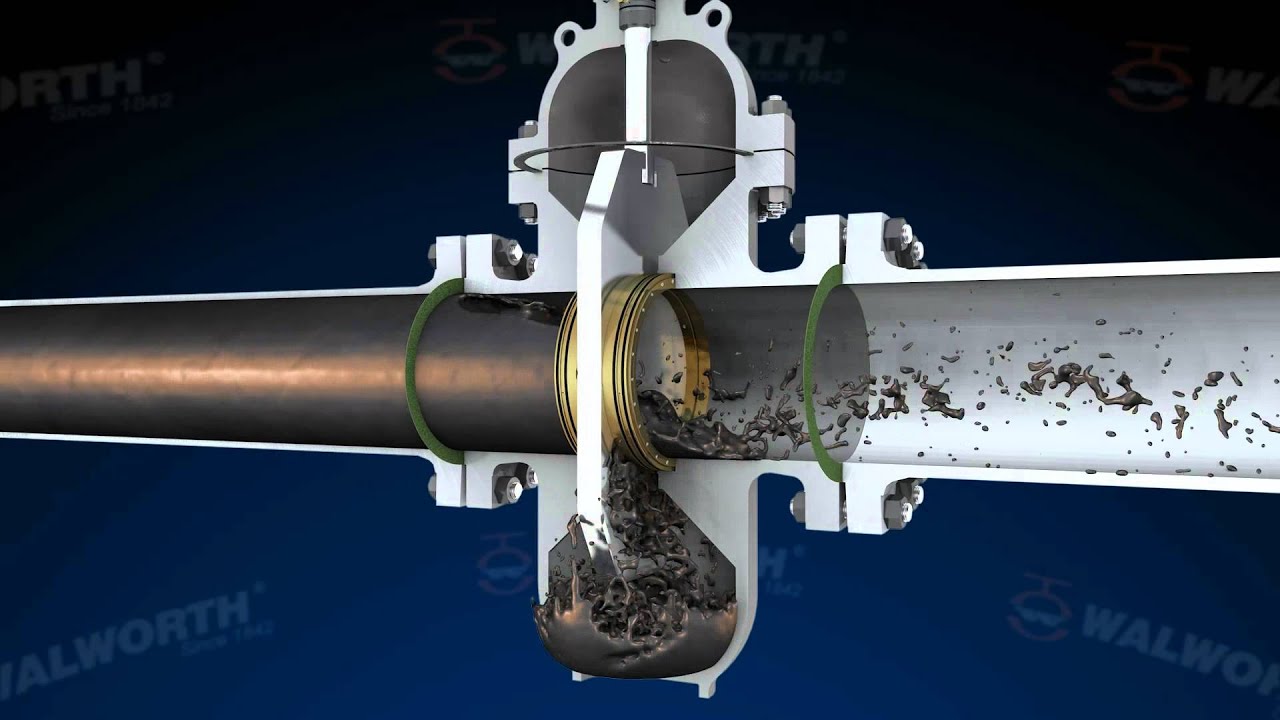

Double expanding gate valve definition. The gate female wedge is driven by the stem and a centralizer mechanism guide helps in retaining the gate segment assembly until sealing through expansion is required. The slopes are designed to cause the expansion of the gate in both open and closed positions with the valve closed the gate provides a double barrier with the valve open a full bore conduit is isolated from. The male and female parts of the wedge are often termed as gate and segment by different manufacturers. Double expanding gate valves are made by two sliding pieces.

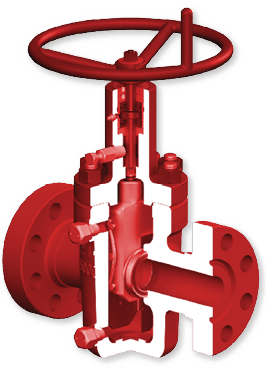

It is a linear motion valve used to start or stop fluid flow. Each segment is machined with a double slope a male and a female. The disc surfaces are always in contact with the body seats. Double expanding gate valves have a gate wedge split into two parts mainly male and female segments.

Normally the gate and segment have a cam retained design control arm or lever lock arm. Construction is available with single expanding or double expanding system. A gate valve is the most common type of valve used in any process plant. A double disk parallel gate valve has two parallel disks that are forced on closure against parallel seats by a spreader they are used for liquids and gases at normal temperatures.

For example in liquid service near waterways or municipalities double expanding gate valves with dbb capabilities such as the cameron wkm pow r seal double expanding gate valve are preferred for critical isolation because they provide a tight mechanical seal simultaneously upstream and downstream which is normally unaffected by pressure. On the other hand the seating force in a single disk parallel gate valve is provided by the fluid pressure acting on either a floating disk or a floating seat. It is also referred to as a slide valve or parallel slide. The double disc parallel seat gate valve is often favored for high temperature steam service because it is less likely to stick in the closed position as a result of change in temperature.

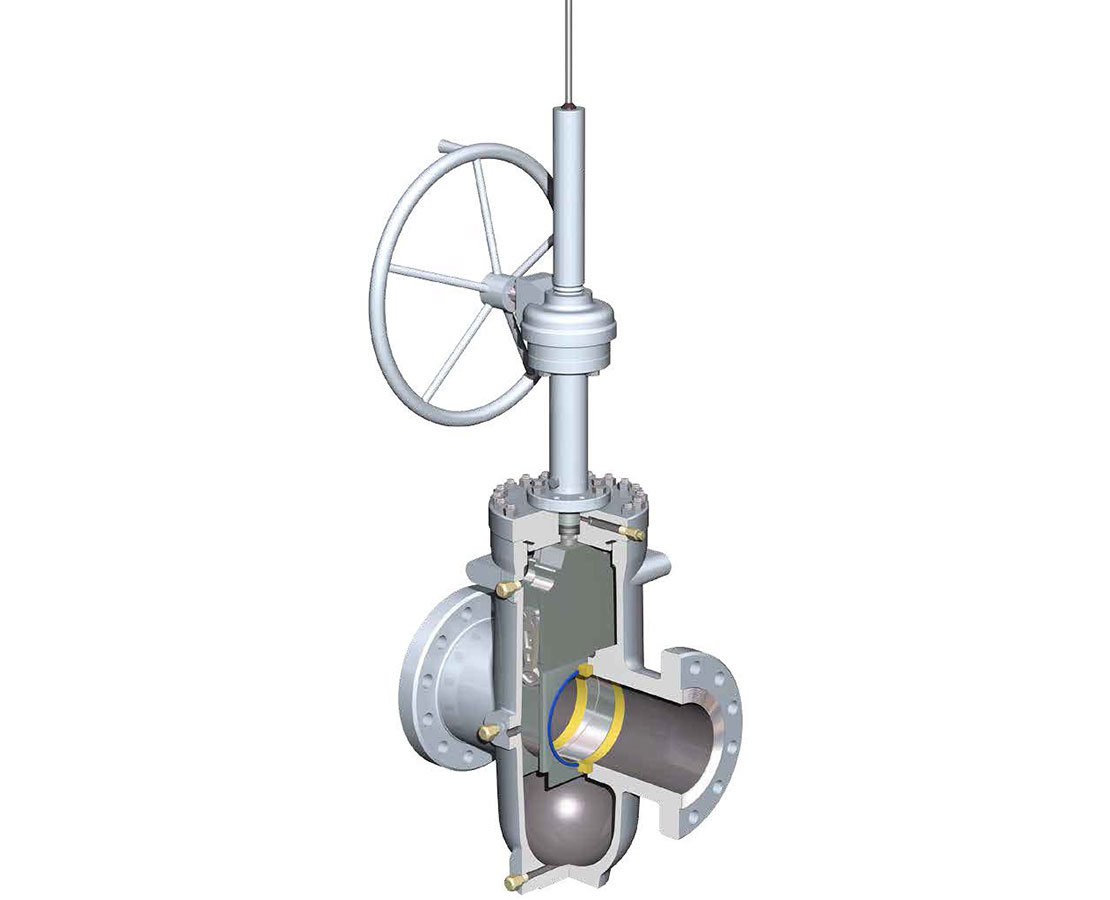

In the second case the same expansion is also obtained in the valve open position. The actual product may vary slightly from shown due to engineering approved variation. The double expanding gate valve is equipped with a two segment gate.